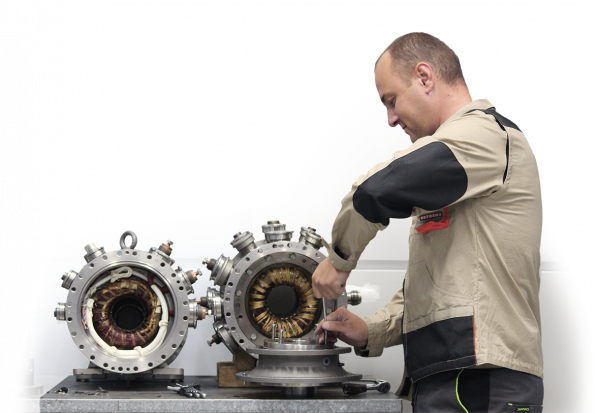

Проектируем и производим высокоскоростные электрические машины по техническому заданию Заказчика

Консультация по услугам

Персональный менеджер подробно ответит на ваши вопросы и подготовит индивидуальное коммерческое предложение.

Задать вопрос

О компании

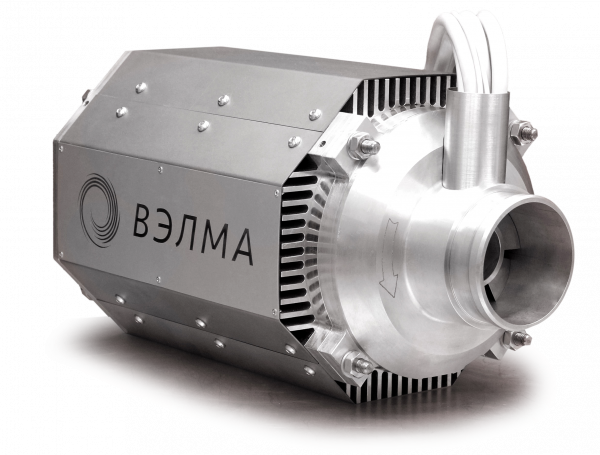

Компания ВЭЛМА – команда опытных специалистов в области электромашиностроения. Деятельность нашей компании направлена на разработку конструкторской документации и изготовление высокооборотистых двигателей на постоянных магнитах.